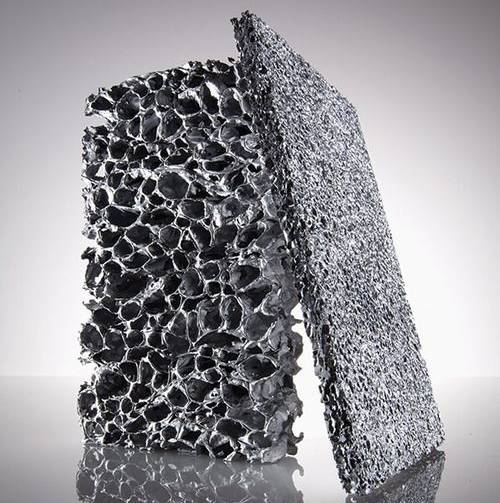

Metallic Foams – Ultra-Lightweight, Good Conductivity

Metallic foams can be made of aluminum, steel, copper or nickel. They are the new generation porous functional materials with unique structure and properties. E.g. high specific surface area, small density, ultra lightweight, good thermal & sound insulation and able to absorb electromagnetic waves. These porous foam metals have been widely applied in aerospace, aviation, transportation, environmental protection, energy, biological and other high-tech or general industrial fields.

As a professional supplier, we can offer metallic foam materials of the following types:

Aluminum foam

Aluminum foam is made of pure aluminum or aluminum alloy by foaming process after adding additives. Thanks to its excellent physical, chemical, mechanical properties and recyclability. Aluminum foam is regarded as one of the most promising engineering materials, especially in the transportation, aerospace and building construction.

Specification

- Size: 800 × 2400 mm or customize.

- Thickness: 4–50 mm.

- Density: 0.25–0.75 g/cm3.

- Poriness: 75% – 98%.

- Energy Absorption: 8–30 J/m3.

- Volume Density: > 0.1 g/cm3.

- PPI: 5–110.

- Bending Strength: 3–15 Mpa.

- Compressive Strength: 3–17 Mpa.

Application

- Oil-water separator material.

- Electromagnetic shielding material.

- Powder sintered salt granule.

- Thermal insulation material.

- Sandwich panel car roof.

- Sound insulation material.

- Sound absorbing material.

- Train compartment material.

Steel foam

Steel foam (foam iron) and its alloy are made of nano- or micro-scale iron powder or iron alloy powder. The microstructure is in the form of open-cell three-dimensional structure with good mechanical and processing properties. Steel foam has micro-nano pore size, and the porosity ranges from 40% to 95%. Besides, the thickness of the material can be as thin as 0.1 mm.

Specification

- Size: 500 × 1000 mm or customize.

- Thickness: 1–25 mm.

- Poriness: 95% – 98%.

- Aperture Ratio: ≥ 98%.

- Volume Density: > 0.1 g/cm3.

- PPI: 5–110.

- Tensile Strength: 8–50 Mpa.

- Compressive Strength: ≥ 250 KPa.

- Mechanical Strength: 2–5 KPa.

- Working Temperature: ≥ 900 °C.

Application

- Floor damping material.

- Filter material.

- Decorative material.

- High-grade packaging material.

- Structural material.

- Battery electrode material.

Nickel foam

Nickel foam is an excellent sound absorbing material, especially at high frequencies. The sound absorption performance in low frequency can be improved by designing the sound absorption structure. Nickel foam is also one of the best electrode materials for making cadmium-nickel batteries and hydrogen-nickel batteries.

Specification

- Size: 600 × 600 mm or customize.

- Thickness: 0.5–40 mm.

- Poriness: 60% – 98%.

- Aperture Ratio: ≥ 98%.

- Volume Density: > 0.1 g/cm3.

- PPI: 20–50.

- Tensile Strength: 8–50 Mpa.

- Compressive Strength: ≥ 250 KPa.

- Mechanical Strength: 2–7 MPa.

- Working Temperature: ≥ 500 °C.

Application

- High temperature resistant ultra-light structure.

- High-grade packaging material.

- High-grade decorative material.

- Battery electrode material.

- Distillation column packing.

- Condenser heat exchange material.

- Chemical catalyst carrier material.

- Floor damping material.

- Shielding material.

Copper foam

The copper foam has good electrical conductivity and ductility. And its preparation cost is lower than that of nickel foam. Copper foams are ideally used as the material for production of battery negative electrode (carrier), catalyst carrier and electromagnetic shielding.

Specification

- Size: max. 600 × 600 mm or customize.

- Thickness: 1–25 mm.

- Poriness: 60% – 98%.

- Aperture Ratio: ≥ 98%.

- Volume Density: 0.1–0.8 g/cm3.

- PPI: 5–130.

- Tensile Strength: 5–18 KPa.

- Compressive Strength: ≥ 250 KPa.

- Mechanical Strength: 2–5 KPa.

- Working Temperature: ≥ 900 °C.

Application

- Thermal management materials.

- Catalyzer.

- Muffler and shielding material.

- Electrode material.

- Filtering material.

- Fluid pressure buffer material.

Practical Application

Aluminum foam for trains making

Aluminum foam for building construction

Copper foam for computer heat dissipation

Metal foam replaces the lamella structure in a model cooler.

E-mail: info@filter-elements.org

Please provide the detail requirements when inquiry to us. It will helps to give a satisfactory answer.